Which type of pump is most commonly used?

Release Time :

2025-02-11

There are many different types of industrial pumps, each designed for a specific use and fluid characteristics. Common types include centrifugal, positive displacement, diaphragm, and submersible pumps.

Centrifugal Pumps

How it works: Centrifugal pumps use an impeller to transfer kinetic energy to a fluid, which is converted to pressure energy as the fluid leaves the pump.

Common Industry Uses:

Water Supply

Wastewater Treatment

Oil and Gas

Chemical Processing

Types of Fluids Pumped:

Water

Oil

Chemicals

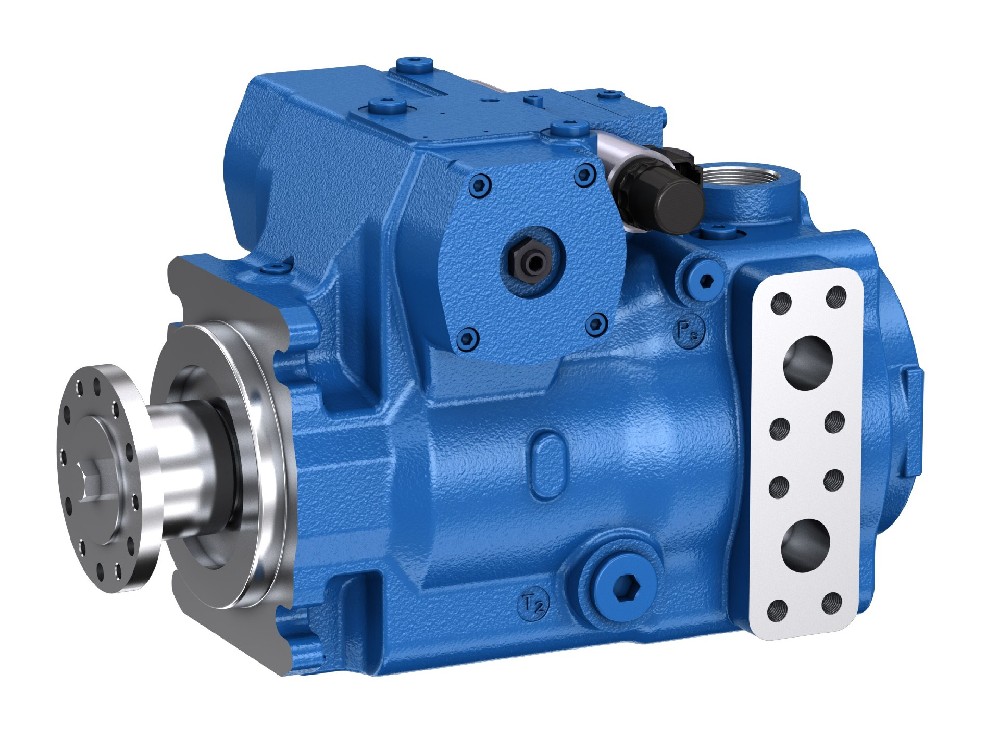

Positive Displacement Pumps

How it works: These pumps move fluids by capturing a fixed amount of fluid and forcing (displacing) it into a discharge pipe.

Common Industry Uses:

Food Processing

Pharmaceutical Manufacturing

Hydraulic Systems

Types of Fluids Pumped:

Viscous Liquids

Slurries

Diaphragm Pumps

How it works: Diaphragm pumps use a diaphragm to move fluids. The diaphragm is pushed and pulled, creating a vacuum that draws in the fluid and then pushes it out.

Common Industry Uses:

Chemical Transfer

Pharmaceutical Manufacturing

Food and Beverage

Types of Fluids Pumped:

Chemicals

Acids

Foods

Gear Pumps

How it works: Gear pumps use gear meshing to pump fluids through displacement.

Functions of Industrial Pumps

Transporting Fluids: The primary function of an industrial pump is to move fluids between locations or processes.

Increasing Fluid Pressure: Pumps are used to increase the pressure of a fluid to move it through a piping system or process equipment.

Circulating Fluids: Pumps are used to circulate fluids in many systems, such as in cooling and heating systems.

Application Areas

Water Treatment: Pumps are used to move water in and out of treatment plants, as well as at various stages of a treatment process.

Chemical Industry: Pumps handle a variety of chemicals, often at high pressure or temperature, or with corrosive or hazardous properties.

Oil and Gas: Pumps are vital in the extraction, transportation, and processing of oil and gas.

Food and Beverage: Pumps are used to handle a variety of liquid ingredients, often with stringent hygiene standards.

Pharmaceuticals: Precision pumps are used to process and manufacture pharmaceuticals.

Agriculture: Pumps are used for irrigation, spraying pesticides, and fertilizing.

Main Features

Capacity and Power: Pumps vary greatly in size and power, depending on the volume and type of fluid they need to handle.

Construction Materials: Pumps are made of materials that are compatible with the fluids they handle, such as stainless steel for corrosive fluids.

Energy efficiency: Modern pumps are designed with a focus on energy efficiency as they are used in a wide range of industries.

RELATED NEWS

2025-02-28

How to diagnose hydraulic problems?

The Importance of Hydraulic Systems in Industrial ApplicationsHydraulic systems are widely used in industries such as construction, manufacturing, agriculture, and aerospace due to their ability to generate significant force with precise co···

2025-02-28

What is the life expectancy of a hydraulic cylinder?

Typical Life Expectancy of a Hydraulic CylinderThe life expectancy of a hydraulic cylinder can vary widely depending on its design, application, and operating environment. On average, a well-maintained hydraulic cylinder can last anywhere f···

2025-02-28

Why is my hydraulic cylinder not retracting?

The Role of Hydraulic Cylinders in Mechanical SystemsHydraulic cylinders are the backbone of many industrial applications, from construction equipment to manufacturing machinery. They operate by converting hydraulic energy into linear motio···

2025-02-28

How to check if a hydraulic cylinder is leaking internally?

Hydraulic cylinders are essential components in many industrial and mechanical systems, providing the force needed to perform heavy-duty tasks with precision. However, like any mechanical system, hydraulic cylinders are susceptible to wear ···

2025-02-28

What is the most common failure on a hydraulic cylinder?

The Role of Hydraulic Cylinders in Industrial ApplicationsHydraulic cylinders are the workhorses of many industrial systems, providing the force required to perform heavy-duty tasks. They consist of a cylindrical barrel, piston, piston rod,···

2025-02-21

What is the most commonly used hydraulic cylinder?

The Most Commonly Used Hydraulic CylinderThe tie-rod hydraulic cylinder is widely regarded as the most commonly used hydraulic cylinder. Its popularity stems from its simple design, ease of maintenance, and cost-effectiveness. Tie-rod cylin···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)