Welcome to WUXI DAHONG HYDRAULIC PNEUMENT CO.,LTD

WhatsApp: 13665121168 Email: shaominjiao@wxdahong.com

-

-

Standard welded high-pressure Hydraulic cylinder

-

Hydraulic cylinder of Drilling jumbo

-

Hydraulic cylinder of tunneling boring machine

-

Hydraulic cylinders for railway equipment

-

Metallurgical electric furnace Hydraulic cylinder

-

Hydraulic system

-

Hydraulic cylinder

-

Hydraulic rams

-

Oil cylinder

-

Basic Hydraulic Cylinders and Systems

-

Custom Hydraulic Cylinder Services

-

Multi-stage and special structure hydraulic cylinder

-

Industrial and agricultural hydraulic cylinders

-

Mobile & Heavy Duty Hydraulic Cylinders

-

Special Application Hydraulic Cylinders

-

Technical Support and Accessories

-

Non-standard customization

-

-

- Home page

- Technology

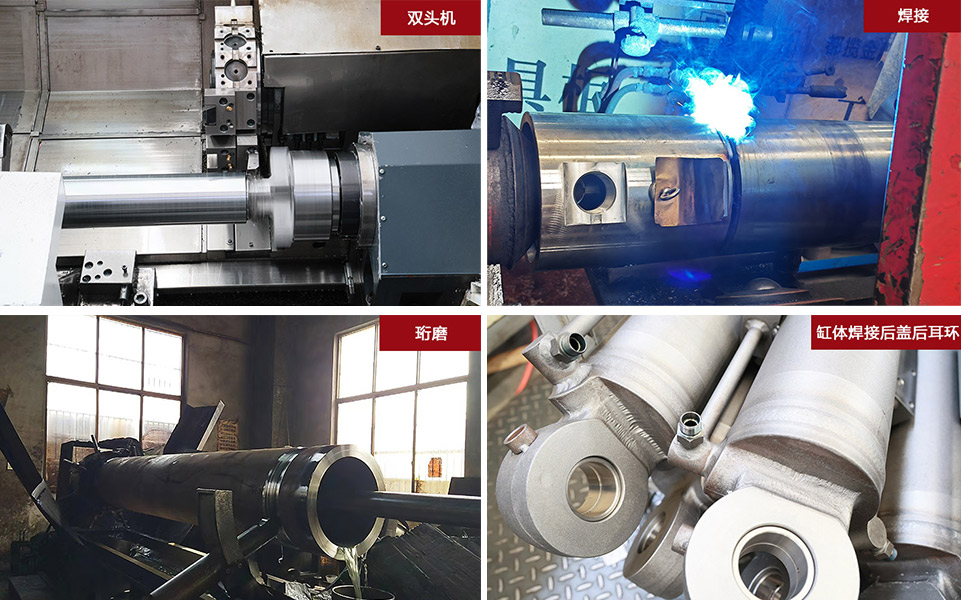

Tube

* Stock preparation:Strict selection of high precision cold drawn pipe materials

* Double head machine:turining total length of the tube/grinding/fine turning the welding postion/processing oil port

* Welding:Weld accessories before honing to avoid cylinder deformation

* Honing:Honing should ensure the straightness and ellipticity of the inner hole

* Fine interior thread:The concentricity of fine internal thread shall not exceed 0.1mm.

* Welded back cover:Adopt professional automatic welding equipment to weld back cover and other accessories.

* Sand blasting:blasting can strengthen the adhesion of paint and ensure the quality of paint.

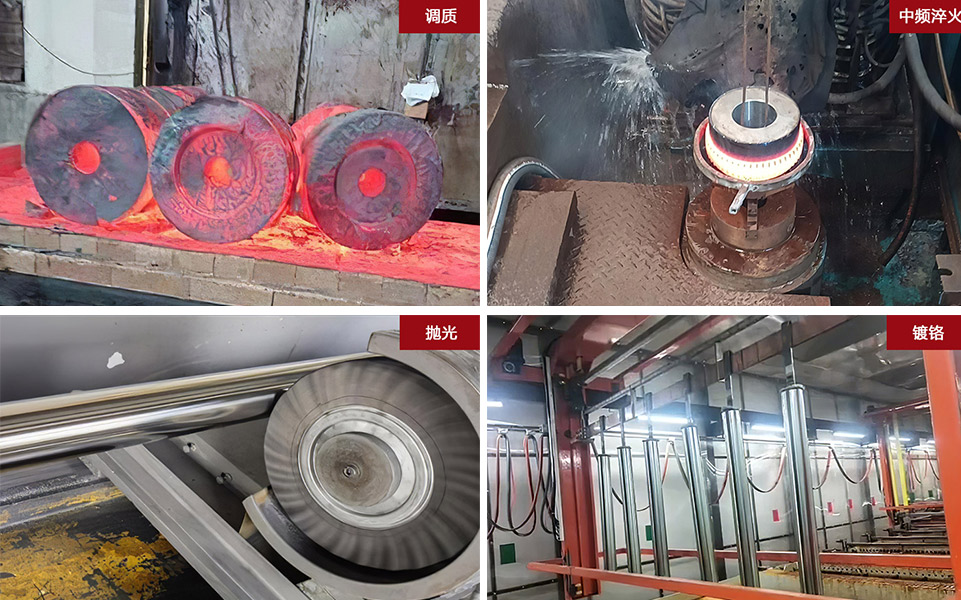

Piston rod

* Rough turning spindle head:Ensure the strength of the thread. Harden and temper after removing margin

* Externalturning:Leave a margin about 1.5-2.5mm

* Hardening and tempering:Heating to 800°, keep warm for 5 hours. The hardness is HRC22-28

* Semi-finished fine turning: external roundturning to machining allowance 0.8-1mm

* Welding : Automatic welding,flaw detection after keeping warm for 12 hours

* Medium freguency hardening:depth :1.5-2mm hardness :HRC45-52

* Coarse grinding:Leave a marginabout 0.25-0.3mm

* Fine turning:Turning the area ofwelding position and thread.

* Turning welding scar : R>5mm,Promise arc connection between frontearing and pistonrod

* Fine grinding : Grinding to the size before chroming

* Polishing :polishing.guarantee the rod's finish before chroming

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)

CONTACT US

Email : shaominjiao@wxdahong.com

Phone : +13665121168

Whatsapp:13665121168

Add : 62 Zhenhu North Road, Hudai Town, Binhu District, Wuxi City

PRODUCT CENTER

Copyright : WUXI DAHONG HYDRAULIC PNEUMENT CO.,LTD