Where is the power source for a hydraulic system?

Release Time :

2025-02-12

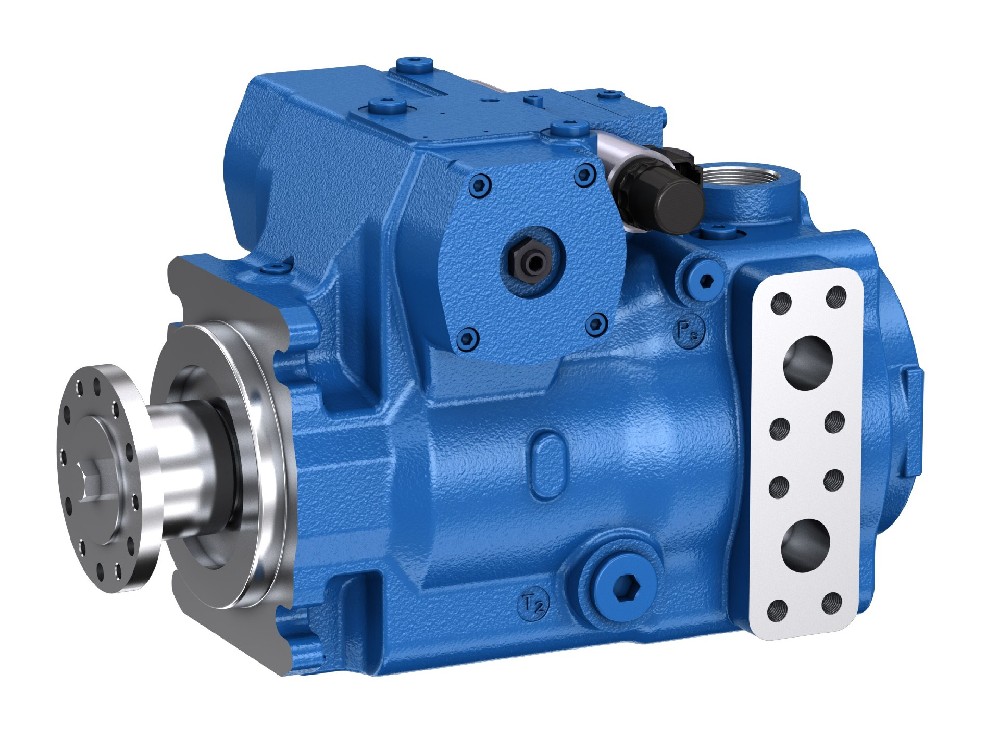

A hydraulic pump is the power source for a hydraulic system, which requires a prime mover (such as an electric motor or engine) to create fluid flow. Hydraulic pumps include positive displacement pumps, which are divided into two categories: fixed displacement or variable displacement. Fixed displacement pumps deliver a fixed amount of fluid per shaft rotation. Variable displacement pumps deliver an adjustable amount of fluid per shaft rotation, depending on the design type. This is achieved by changing the inclination angle of the swash plate, the inclination angle of the bent shaft, or changing the eccentricity of the cam. Some pumps can achieve variable displacement by rotating their port plates. Examples include gear pumps, vane pumps, and piston pumps. Hydraulic power sources rely on many components working together to form a complete hydraulic system.

The term hydraulic power generally refers to the power generated by hydraulic fluid when it is pressurized and moved. A hydraulic power source provides the energy required to operate a hydraulic system, and there are various types of hydraulic power sources available for different applications. The general name for an external hydraulic power source is a "hydraulic power unit." It is sometimes also called a **hydraulic pump** or a hydraulic power pack. A hydraulic power unit is a compact assembly that typically includes a hydraulic pump, a motor, and a reservoir. The pump pressurizes the hydraulic oil and then delivers it to the system through a series of hoses and valves. In summary, the common name for an external hydraulic power source is a hydraulic power unit. It is a compact assembly that includes a hydraulic pump, a motor, and a reservoir. The hydraulic power unit pressurizes the hydraulic oil and then delivers it to the system through a series of hoses and valves.

RELATED NEWS

2025-02-28

How to diagnose hydraulic problems?

The Importance of Hydraulic Systems in Industrial ApplicationsHydraulic systems are widely used in industries such as construction, manufacturing, agriculture, and aerospace due to their ability to generate significant force with precise co···

2025-02-28

What is the life expectancy of a hydraulic cylinder?

Typical Life Expectancy of a Hydraulic CylinderThe life expectancy of a hydraulic cylinder can vary widely depending on its design, application, and operating environment. On average, a well-maintained hydraulic cylinder can last anywhere f···

2025-02-28

Why is my hydraulic cylinder not retracting?

The Role of Hydraulic Cylinders in Mechanical SystemsHydraulic cylinders are the backbone of many industrial applications, from construction equipment to manufacturing machinery. They operate by converting hydraulic energy into linear motio···

2025-02-28

How to check if a hydraulic cylinder is leaking internally?

Hydraulic cylinders are essential components in many industrial and mechanical systems, providing the force needed to perform heavy-duty tasks with precision. However, like any mechanical system, hydraulic cylinders are susceptible to wear ···

2025-02-28

What is the most common failure on a hydraulic cylinder?

The Role of Hydraulic Cylinders in Industrial ApplicationsHydraulic cylinders are the workhorses of many industrial systems, providing the force required to perform heavy-duty tasks. They consist of a cylindrical barrel, piston, piston rod,···

2025-02-21

What is the most commonly used hydraulic cylinder?

The Most Commonly Used Hydraulic CylinderThe tie-rod hydraulic cylinder is widely regarded as the most commonly used hydraulic cylinder. Its popularity stems from its simple design, ease of maintenance, and cost-effectiveness. Tie-rod cylin···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)