Welcome to WUXI DAHONG HYDRAULIC PNEUMENT CO.,LTD

WhatsApp: 13665121168 Email: shaominjiao@wxdahong.com

-

-

Standard welded high-pressure Hydraulic cylinder

-

Hydraulic cylinder of Drilling jumbo

-

Hydraulic cylinder of tunneling boring machine

-

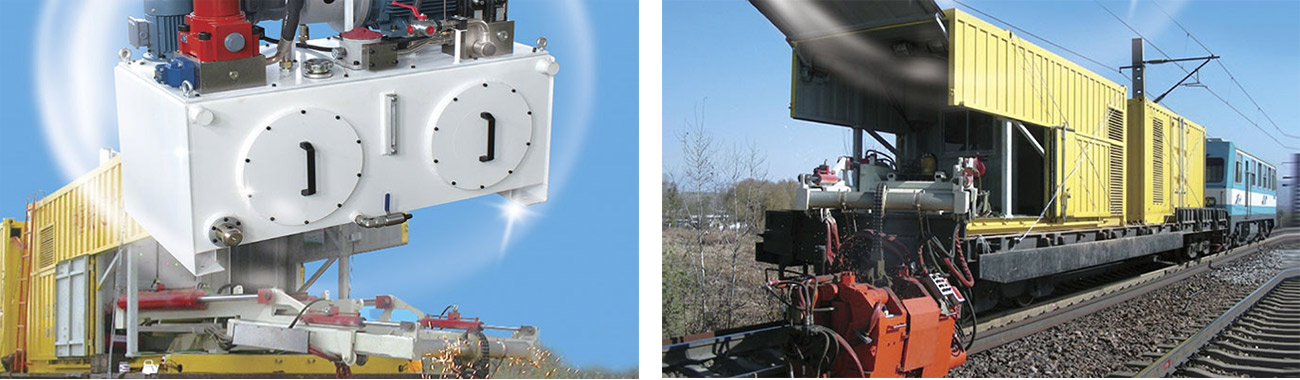

Hydraulic cylinders for railway equipment

-

Metallurgical electric furnace Hydraulic cylinder

-

Hydraulic system

-

Hydraulic cylinder

-

Hydraulic rams

-

Oil cylinder

-

Basic Hydraulic Cylinders and Systems

-

Custom Hydraulic Cylinder Services

-

Multi-stage and special structure hydraulic cylinder

-

Industrial and agricultural hydraulic cylinders

-

Mobile & Heavy Duty Hydraulic Cylinders

-

Special Application Hydraulic Cylinders

-

Technical Support and Accessories

-

Non-standard customization

-

-